What's the difference between litho and digital print?

Litho Printing vs Digital Print, Which Is Best?

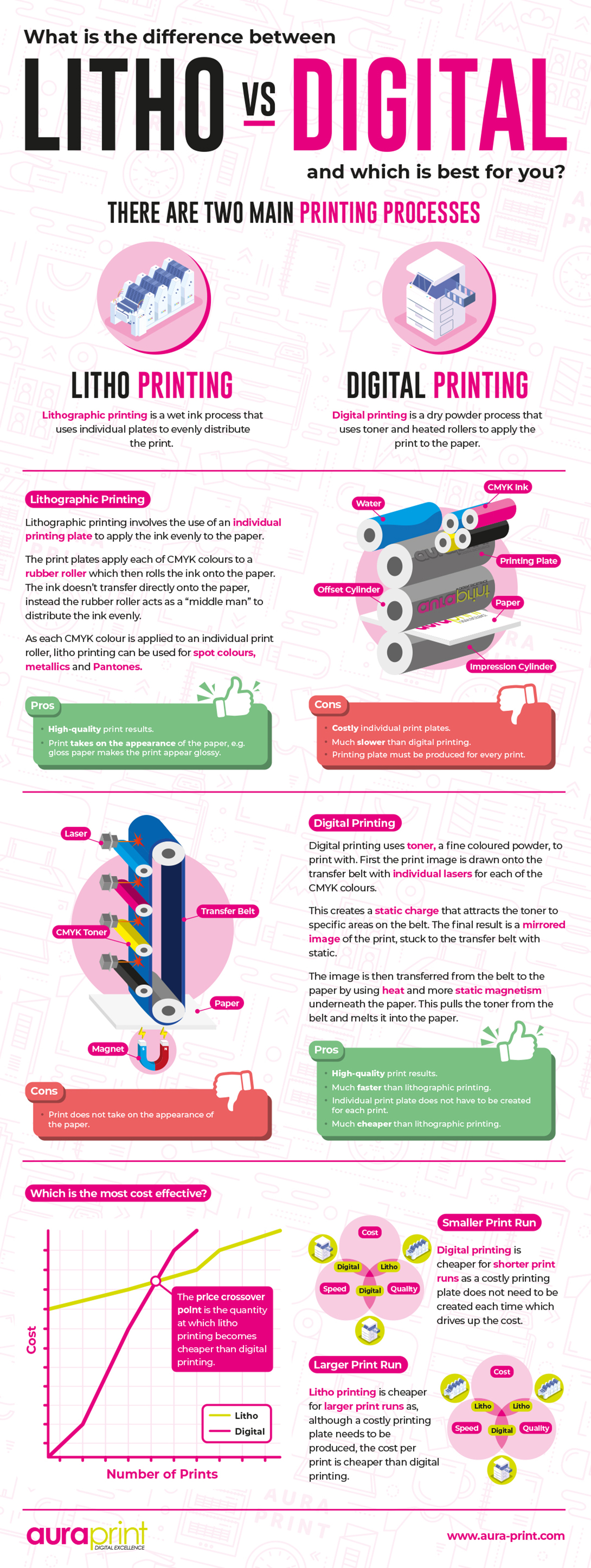

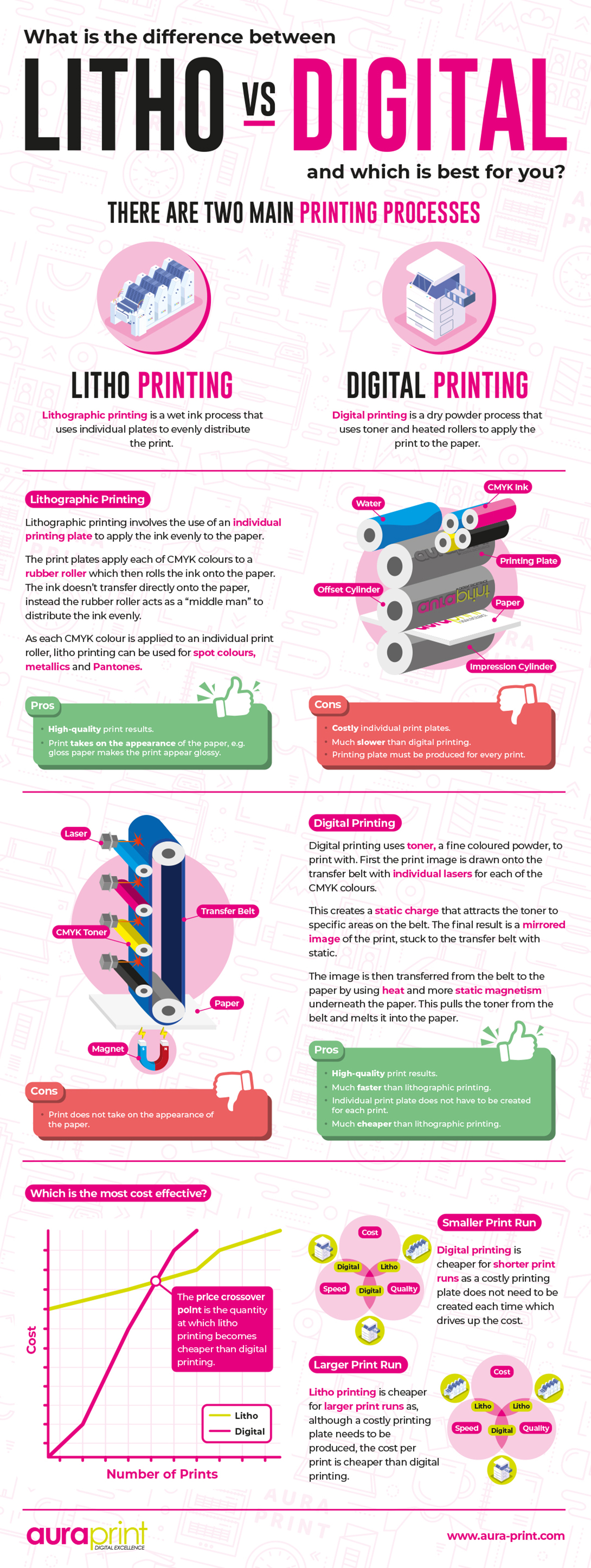

In the world of printing, there are two main production methods: digital and litho. Essentially, digital printing is a dry powder process while lithographic printing is a wet ink process. Both use completely different technologies, and both have their own pros and cons.

There is a lot to be said about the two different printing methods, but in this guide, we'll stick to the most important considerations: print quality, speed, and cost. But first, let's start with a look at how digital and litho printing work.

Digital And Litho Printing – How They Work

Digital and litho printing are two completely different printing methods, and each has its own strengths. Knowing the key differences between the two will help you decide which process is right for your print job, especially if you're looking to print flyers and leaflets in large numbers.

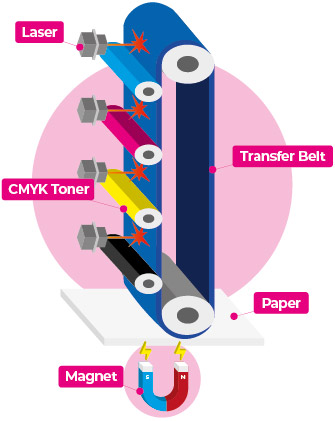

Digital print machines are essentially just large laser printers, like the printer you might have in your office – except these machines print much faster, and to a very high quality.

Digital print machines use toner to print with, which is a very fine coloured powder. First, the print image is ‘drawn’ onto the machine's printing drum by a built-in laser. This creates a static charge on the drum cylinder, which reflects the image to be printed. The fine toner powder then sticks to this static, like a balloon would stick to the wall after you rub it on your hair.

This process happens for all four CMYK colours (Cyan, Magenta, Yellow and Black) to create the finished print image on the drum. This image is then rolled onto the paper at high speed, and heated (or 'fused') to melt the toner powder and set it in place on the paper fibres.

The heat method of fusing the toner to the page, and the mechanism of the machines, means that they can print onto paper in the range of 90gsm - 350gsm. Digital printing can also give very interesting effects when it's used to print onto textured paper.

Litho flyers printing is the more traditional printing method of the two, and dates back to 1796 in one form or another. This process uses wet ink and fast-moving rollers, which rely on individual printing plates to act like a series of stencils against the printing paper.

Lithographic printing plates are made using a traditional photographic process, or a more modern CTP (Computer-to-Plate) system. These print plates are used to apply each of the four CMYK colours to a rubber roller, which then applies the print image evenly to the paper. This is also known as offset litho printing, because the image is ‘offset’ from the plates to the roller, before finally going onto the paper. This just means that the ink doesn't transfer directly onto the paper; instead, it uses the rubber roller as a 'middle man' to distribute the ink evenly.

The ink used in this process is a thick liquid, rather than the toner powder used in digital printing, and it's applied to the print rollers individually. This means that litho printing can use special spot colours, metallics and Pantones too. Litho can also print on a slightly wider range of paper weights, from light card all the way up to heavier paper stock to make ultra thick litho business cards.

Print Quality

It's typically accepted that litho printing produces higher-quality results than digital printing. But as technology advances, that gap has grown so small that it's actually very hard for people to tell the difference. However, if your print design includes large blocks of solid colour or gradients, then litho printing may still be the better option as these elements will look a little smoother.

Between digital and litho, the actual finish of the print is different too. With litho printing, the ink soaks further into the paper fibres. With digital, it sits on the paper's surface.

When it comes to full-coverage print, digital printing will look almost the same regardless of the type of paper it is printed on, i.e. glossy, silk or uncoated – it will have a silky appearance on each type of paper.

With the litho process the paper type is more apparent, so even full-coverage print will take on the appearance of the paper. If you've ever seen a really glossy leaflet, it will have been printed using litho. Litho also makes it easier to print on textured paper, as well as printing on coloured paper.

Speed

Digital: 2-3 days Litho: 7 days

Digital machines don’t have a setup stage before printing begins. We simply drop a PDF file into the computer, put the correct paper into the machine, and press the ‘print’ button. Our digital machine will then print 4,800 sheets of SRA3 paper per hour.

On the other hand, litho presses have a setup period where the printing plates need to be made from the print file. But once the printing process actually starts, lithographic machines are faster than digital printers, with speeds of 18,000 sheets of SRA3/SRA2 per hour not being uncommon.

Cost

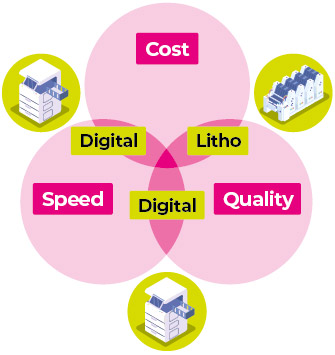

Digital: Shorter Print Runs Litho: Larger Print Runs

As digital machines don’t have a setup procedure, they also don’t have a setup cost. It doesn't cost a penny until you press Print, and then you’re just paying for the paper and what’s known as a ‘click’ charge: each sheet that goes through the machine costs a set amount.

Litho machines use bespoke printing plates which need to be made before printing can begin. This means that there is an upfront cost to litho printing, before you even take paper and ink into account. However, after the setup cost, litho is then cheaper per sheet than digital (and faster too).

So Which Is Right For You?

High-quality digital printing is ideal for most budgets and smaller print runs, especially for prints ordered online. For most people, a fast turnaround on their finished prints is the top priority, along with affordability and a wide choice of papers to personalise their print items. On these scores, digital is the way to go.

Lithographic printing tends to see more business from established brands and larger organisations, or for premium prints on textured and coloured papers. If you're printing large amounts of letterheads in specific brand colours, for example, or need to produce high-end leaflets and magazines in their thousands, then litho could well be a more economical option depending on the size of the print run. If that real premium quality is paramount, or if you need to print in specific spot colours and Pantones, then litho print is likely your best option.

If you'd like to discuss both methods for your particular print job, just get in touch. We'd love to help you choose the best printing method to suit your needs.

USA

USA FR

FR