Kiss Cut Vs Die Cut: Which Should You Choose?

Are you curious about selecting the ideal cutting method for your next batch of custom shape stickers? Well, you’re in the right place. Today we are talking about the differences between the die cut and kiss cut methods of custom sticker printing. We are also discussing when they may be best suited for your sticker printing needs, and how die cutting other items will encourage your decision making process for future creative projects.

What Does Kiss Cut Mean In Printing?

All stickers are made from two layers – the adhesive-backed paper (the sticker itself) and an under sheet (the bit you peel off when you want to stick your sticker). However, instead of cutting out a traditional square or rectangular design with a guillotine, kiss cutting allows for custom shaped sticker printing following the contours of the design without separating the design from the backing sheet.

To do this, a two layer sheet is first printed with the sticker designs. Then, a metal blade cuts through the top sheet, separating the kiss cut shape without cutting through the bottom sheet. This allows the paper backing to remain intact, holding all the cut to shape stickers together on the same sheet.

Stickers can be made in a variety of materials for a multitude of purposes. Our paper stickers are designed for indoor use and are a cost effective way to create promotional materials, celebratory decorations or retail price tags. Waterproof vinyl stickers have a higher durability and are better suited for applications such as car decals or personalising tech or sports equipment as they are weather resistant.

Kiss cut stickers have an abundance of benefits. They have an extended backing sheet which means they can have more complex design capability due to how easy they are to peel. These backing sheets can even contain additional information about your brand or mission statement if you wish to include it. Kiss cut stickers are also easier to store and transport because they include the full backing sheet which lowers the chance that they may bend, fold or become scratched when stored.

Sticker Sheets

A fun extra to add to your online store

or to include with each of your orders!

Order Packaging

Great for sealing packaging and envelopes,

plus no-one will see the gaps in the sheet!

How Does Die Cutting Differ From Kiss Cutting?

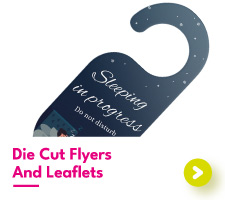

Die cutting is another method that can be used to intricately cut stickers, but it is not exclusively used for sticker printing so this method offers far more product versatility. Die cutting requires a metal stamp (or blade) to cut all the way through the desired material. For stickers, die cut items do still have their own backing sheet, but this backing sheet is identical in size to the sticker itself which may prove trickier to peel than kiss cut stickers.

While they may be trickier to peel than kiss cut stickers because they are loosely packed, die cut stickers are far better suited to be gifted at networking events, or popped into goodie bags for clients and customers, adding a touch of post-event excitement. And of course if you are printing items that are not stickers, then die cutting is the most suitable option as the result is individually printed items in contrast to the kiss cut items which remain attached to their backing sheet. Where kiss cutting is bound to creating stickers, die cutting is a lot more versatile and can be used to create many more product lines.

Die cutting is an exceptionally popular method of cutting unique items, and creating custom products and unique customer experiences. Die cutting (sometimes referred to as a contour cut) can be used to create a huge variety of print products allowing you to showcase your unique personality, your business flair, and communicate your desired style to your target audience.

Kiss Cut Stickers

The die pierces the first layer only, leaving the stickers

attached to the orginal sticker sheet

Die Cut Stickers

The die cuts through the entire sheet, resulting in multiple

individual stickers cut to custom shape

Die Cutting: A Cut Above The Rest

As previously mentioned, a die cut design is more than capable when it comes to cutting stickers, but there is a lot more you can achieve with die cutting. Read on for some wonderfully innovative ideas on how to stand out in the world of creative marketing!

You could create unique invitations such as champagne flute wedding invites, which are the perfect way to create memorable keepsakes for your loved ones during the build up to your life-changing celebration.

How about innovative business branding? Maybe you own a retro gaming restoration business and would appreciate an 8 bit die cut business card to level up your branding for your clientele, or it could be that you need a trowel-shaped business card to reflect your new landscape gardening venture.

Is your Community Book Club in need of rebranding? How about reanimating the group chat with custom bookmarks in the form of a ouija board! You could create a real-life spooktastic page saver while your latest ethereal horror unravels. And if horror novels aren’t your speed, consider fun balloon-shaped die cut bookmarks to welcome new members to your group.

Get cozy with fashionable merchandising ideas! Shake off the winter cold with die cut snowflake swing tags for your cozy collection of fashionable winter warmers. You could remind your customers that your spring/summer collections are on the way with spring-themed custom cut flyers.

There are many additional die cut applications you could make use of to create unique products and experiences, such as perforated event tickets, tear offs for your new dog walking or window cleaning services, interactive marketing materials and double sided promotional materials. The possibilities for die cutting are only bound by your imagination!

We’d love to hear from you wherever you are in your design process! The team at Aura Print is always happy to help and we love talking shop with creatives!

Sticker Packs

Create your own sticker packs or mystery

sticker bundles with die cutting

Order Extras

Treat your customers to a cute freebie with their order,

they're bound to love these custom cut stickers!

Die Cut Or Kiss Cut – Why Not Both?

In a head-to-head, die cut stickers vs kiss cut stickers, you may be wondering, can I have the benefits of both a die cut and kiss cut sticker on the same item? And you can, through our technique of Padding.

At Aura Print, we understand that visually appealing stickers also need to have functionality and accessibility, so we offer sticker options that benefit from being kiss cut and die cut. We achieve this by offering stickers that have additional padding around them.

Padding is fantastic if you have difficulty peeling stickers and are generally put off by the idea of separating the layers with your fingernails. Padding can really bring back that “peel good” factor to sticker peeling.

The process of padding involves adding a peel border around your sticker design (approximately 5 mm wide). This extra area won’t be part of the sticker itself, and it usually stays white like the backing sheet beneath. With padded stickers, the sheet is first kiss cut to the specific shape you require for your sticker. Then the sticker is die cut as a slightly larger item. The die cutting lands, not on the kiss cut shape, but approximately 5 mm larger than the sticker design to create the padding. This results in one sticker receiving two unique cuts. The sticker remains exactly the same dimensions whether it is a kiss cut or die cut sticker, but the paper backing is expanded ever so slightly, allowing the sticker to be peeled with a lot more ease.

By offering this type of sticker you are offering a wider appeal, added inclusion and making stickers more accessible for more people to enjoy as part of a broader audience.

The purpose of your Sticker Purchase?

So whether you are contemplating die cut stickers for your next networking event, or you’re handing out kiss cut sticker sheets to your class, we can certainly cater to your specific needs. We discussed what are die cut stickers along with their benefits, and also explained how kiss cut stickers differ from die cut stickers. They both have a useful place in your creative toolkit.

The difference between die cut and kiss cut stickers fundamentally comes down to whether you are applying the sticker yourself, or whether you are giving the sticker away to others to stick.

So now we understand both the kiss cut and die cut methods of printing and shaping, we need to consider the reason behind your next sticker project, as it can be a great indication as to which method of printing you require. If you are looking to complete a run of stickers, then it may become apparent that you will benefit from kiss cut stickers over die cut due to the aforementioned easy peel usage. Perhaps you are handing out goody bags at a children’s birthday party and wish to add some colorful easy-peel sticker sheets? Maybe you require an elegant printed candle sticker design to add the finishing touches to your latest range of home decor. These applications would certainly be better suited towards a kiss cut sticker printing method.

Alternatively, you may be the next Green Day and you want to bundle your new limited edition band stickers with your latest EP. Or you may be a Twitch streamer who wishes to send out some easy to ship custom merchandise to your viewers. You would be best suited choosing a die cut sticker printing method for the best results.

Kiss Cut vs Die Cut Stickers - Ask Our Team For Advice

If you happen to be looking for products that are not stickers, then you would be best suited looking at our die cutting options for custom and unique shaped business materials.

It’s perfectly acceptable to not have a concrete idea cemented in your mind yet, or potentially you may still be in the brainstorming phase with a few artboards or reference images cluttering up your desktop. You may know you love the concept of having a quick and easy memento to give to your supporters, friends, classroom or clients, or you may be looking for a way to finalise the perfect finishing touch for your latest product or packaging. That’s a very exciting stage of the creative process, as you can look online for inspiring artwork, fonts, colour schemes, styles and applications that may help you to develop your initial idea.

If you are still unsure about die cut vs kiss cut stickers, the team here at Aura Print offer a variety of options for stickers. The team will also be happy to work from your detailed design brief if you have not finalised your composition. You can also request a sticker sample pack to inspect the different materials in person before you complete your order.

UK

UK FR

FR