How Holographic Foil Is Made

Holographic foil has become increasingly popular in various industries due to its visually striking and versatile nature. Understanding the production process behind holographic foil is essential in appreciating the intricate artistry involved. In this post, we will delve into how holographic foil is made and explore the fascinating world of holography.

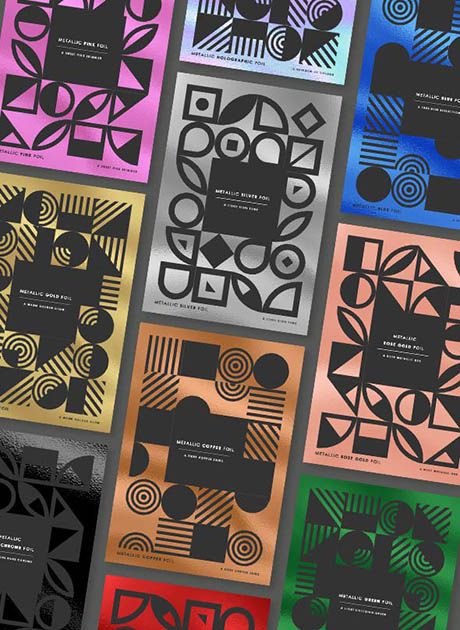

What is Holographic Foil?

Holographic foil comprises of a thin, metallic sheen that, when exposed to light, reveals a captivating holographic effect, showcasing a depth and dimensionality that mimics three-dimensional spaces. This eye-catching feature has found widespread application across various domains, notably in enhancing the packaging of products, elevating brand identity, and introducing a dynamic element to the realm of special effects in the entertainment sector. Its ability to infuse a product with a perception of luxury and innovation is particularly valued by brands aiming to differentiate themselves in the marketplace. By employing holographic foil, entities across industries can significantly boost the aesthetic appeal and tactile experience of their offerings, ensuring they capture and retain consumer attention in an increasingly competitive environment.

Materials Used in Holographic Foil Production

The foundation of holographic foil lies in the judicious selection of base materials, integral to the production process. Polyester film, renowned for its durability and clarity, serves as the primary substrate, facilitating the intricate holographic patterns that characterize these foils. To achieve the desired holographic effect, an array of coatings and adhesives is meticulously applied to this film. These layers not only contribute to the visual impact but also ensure the longevity of the hologram. Furthermore, the incorporation of specific pigments and metals is crucial in enhancing the foil's reflective qualities. Metals such as aluminum are favored for their ability to reflect light, creating the vivid and dynamic visuals synonymous with holographic foils. This careful amalgamation of materials underpins the creation of foils that captivate with their depth, motion, and shimmer, heralding a new dimension in packaging and product design.

The Holographic Pattern Creation Process

The process of creating holographic patterns is an intricate dance of physics and artistry, where light is the primary artist. Employing lasers and a variety of optical elements, the method involves capturing the complex interference patterns that light waves create when they meet. These patterns, once recorded, offer a mesmerizing depth and movement to the holographic images that are eventually showcased on the foil. Diverse in their application, the patterns can range from the visually fluid rainbow designs to the more structured appearances of 2D/3D and dot matrix holography. Each style has its unique charm and application, serving different aesthetic and functional purposes. But it's a purpose that will serve everything from beautiful invites through to eye catching art prints and premium business cards. This stage is pivotal, as it sets the groundwork for the transformative appearance that holographic foil is renowned for, making it a crucial component in the foil's production journey.

Production Steps

The journey to produce holographic foil commences with the mastering phase, where precise laser technology crafts the original hologram through intricate interference patterns. Following this, the electroforming stage creates a metallic duplicate of this master, setting the stage for embossing. During embossing, the holographic design is impressively stamped onto a plastic film under conditions of elevated heat and pressure, ensuring the pattern's fidelity. The subsequent metallization process involves the deposition of a thin aluminum layer onto the embossed film, significantly boosting its reflectivity and thus, the overall holographic effect. The final stage, laminating, encapsulates the film in protective layers, safeguarding the holographic marvel against wear and tear, thereby enhancing its longevity. Each step is meticulously carried out, ensuring the highest quality and durability of the holographic foil, ready for its myriad applications across industries.

Quality Control in Holographic Foil Production

Maintaining the excellence of holographic foil demands rigorous quality assurance practices throughout its manufacturing. The quality control process encompasses meticulous inspections at every stage, from scrutinizing the holographic patterns to evaluating the precision of embossing and the uniformity of the metallization layer. It is imperative to conduct thorough assessments to ensure that each batch of foil exhibits consistent brilliance and durability, aligning with industry standards. Durability tests are integral, verifying that the foil can withstand the rigors of its intended applications without compromising its aesthetic integrity. By adhering to stringent quality protocols, manufacturers can uphold the reliability and allure of holographic foil stickers, flyers, cards and more, securing its place as a premium choice in the market.

Environmental Considerations

The production of holographic foil, whilst remarkable for its visual outcomes, poses challenges to environmental sustainability. Recognizing this, the industry is actively seeking methods to lessen its ecological footprint. Innovations include the development of biodegradable substrates as alternatives to conventional polyester films, and the introduction of solvent-free adhesives to minimize harmful emissions. Recycling plays a pivotal role, with initiatives aimed at reprocessing used foil and the materials involved in its creation. Additionally, advancements in manufacturing efficiency are continually pursued to reduce waste and energy consumption. These efforts signify a committed stride towards reconciling the demand for this captivating material with the imperative of environmental stewardship.

Applications and Benefits of Holographic Foil

The deployment of holographic foil transcends aesthetic enhancement, offering tangible benefits across an array of applications. In the realm of packaging, it not only captivates consumers with its dynamic visual impact but also serves as an efficacious anti-counterfeiting measure, thereby bolstering product security. Marketers leverage its unique appeal to elevate brand presence and create memorable customer experiences, distinguishing their offerings in a saturated marketplace. Furthermore, the application of holographic foil in promotional materials and event decorations introduces a layer of sophistication and engagement, encouraging interaction and leaving a lasting impression. This versatility underscores the foil's value beyond mere decoration, making it an integral component in strategies aimed at innovation and differentiation. Its capacity to merge aesthetic allure with practical functionalities makes holographic foil a preferred choice for forward-thinking brands and creatives alike, eager to explore new dimensions in presentation and protection.

UK

UK FR

FR